How to custom optical filter

Thursday, April20, 2023

Optical filters are an essential component in many applications, including photography, spectroscopy, and optical communication. They are used to selectively transmit or block specific wavelengths of light, providing a means to control the spectral content of an optical signal. While there are many commercially available optical filters, sometimes custom optical filters are required for specific applications. In this article, we will discuss the process of custom optical filter design and fabrication.

How to custom optical filters?

Step 1: Define the Specifications

The first step in designing a custom optical filter is to define the specifications. The specifications will depend on the application and the requirements of the optical system. Some of the critical parameters that need to be defined include:

- Wavelength range: The range of wavelengths that need to be transmitted or blocked.

- Transmission or blocking range: The percentage of light that needs to be transmitted or blocked within the wavelength range.

- Polarization: The polarization state of the incident light, which may affect the filter’s performance.

- Angle of incidence: The angle at which the light will be incident on the filter.

- Temperature and environmental conditions: The temperature and environmental conditions in which the filter will be used.

Once these specifications are defined, the filter design process can begin.

Step 2: Choose the Filter Type

There are various types of optical filters, including interference filters, absorptive filters, and dichroic filters. The choice of filter type will depend on the application and the specifications defined in step 1.

Interference filters are the most common type of optical filter and are based on the interference of light waves. They consist of multiple layers of dielectric materials with alternating high and low refractive indices. Interference filters can provide high transmission or blocking levels over narrow wavelength ranges.

Absorptive filters, on the other hand, absorb specific wavelengths of light. They are made of materials that have strong absorption at the desired wavelengths.

Dichroic filters reflect or transmit specific wavelengths of light, depending on the polarization state. They are made of thin layers of metal or dielectric materials.

Step 3: Design the Filter

Once the filter type is chosen, the filter design can begin. The design process involves determining the number and thickness of the filter layers required to achieve the desired spectral characteristics.

Filter design can be performed using specialized software that can simulate the optical properties of the filter. The software can optimize the layer thicknesses and materials to achieve the desired specifications.

Step 4: Fabricate the Filter

After the filter design is finalized, the filter can be fabricated. The fabrication process will depend on the filter type and the materials used. Interference filters can be fabricated using thin-film deposition techniques, such as sputtering or evaporation. Absorptive filters can be fabricated using dyeing or coating techniques. Dichroic filters can be fabricated using thin-film deposition techniques or etching.

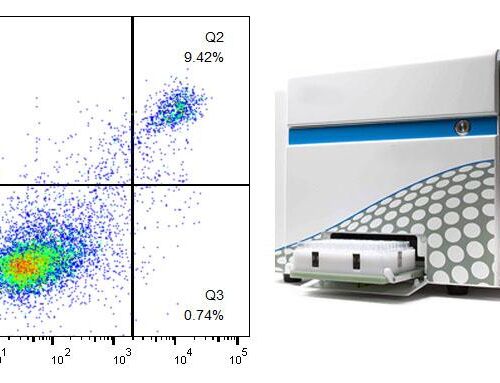

Step 5: Test the Filter

Once the filter is fabricated, it needs to be tested to ensure that it meets the desired specifications. The testing process involves measuring the filter’s transmission or blocking characteristics using a spectrophotometer. The polarization dependence of the filter can also be measured.

In conclusion, designing and fabricating a custom optical filter requires careful consideration of the application’s specifications and filter type. With the right tools and techniques, a custom optical filter can be designed and fabricated to meet the specific requirements of the application.