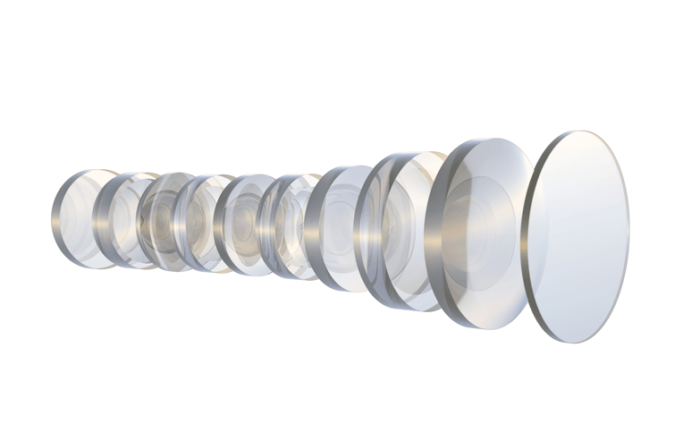

Optical Thin Film Coating Production Capability

Coligh Optics is a leading manufacturer of optical glass filter coatings, offering a wide range of solutions to meet the needs of their customers. We are specialize in utilizing three different thin film coating techniques: Sputtered coating, Ion Assisted Deposition (IAD), and Vacuum coating.

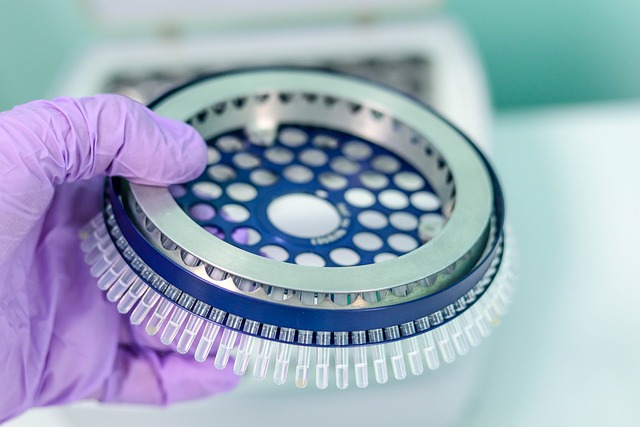

Coligh Optics utilizes the sputtering technique to produce optical glass filter coatings, particularly fluorescence filters, that meet stringent standards for stability, uniformity, and film thickness. This technique allows for the precise deposition of thin films of material onto a substrate, resulting in coatings with exceptional optical properties.

Sputtering is a common method used in the production of optical filters, and it offers several advantages over other coating methods. Here are some of the advantages of sputtered coating when coating optical filters:

- Precise control of film thickness: Sputtering allows for very precise control over the thickness of the coating. This is important in the production of optical filters, as the thickness of the coating determines the filter’s optical properties. With sputtering, the thickness of the coating can be controlled down to a few nanometers, allowing for highly accurate and consistent coatings.

- Uniformity: Sputtering produces coatings that are highly uniform, both in thickness and in composition. This is important for optical filters, which require a uniform coating to ensure that the filter performs consistently across its entire surface. Sputtered coatings are highly reproducible and can be scaled up for high-volume production.

IAD( Ion Assisted Deposition) coating is another hard optical thin film coating technique Coligh applied. IAD is a technique that involves using a high-energy ion beam to bombard the substrate during deposition. IAD (Ion Assisted Deposition) coating has several advantages over optical filter coating.

- This process provide a better better adhesion to the substrate than optical filter coatings. This is because IAD coatings are deposited using ion beams, which help to compress and densify the coating, resulting in a stronger bond between the coating and substrate.

- It also can improve durability of the optical filters. . This is because the ion beams used in IAD coatings create a denser coating that is less prone to cracking or peeling.

- Enhanced optical performance: IAD coatings can provide superior optical performance compared to optical filter coatings. This is because the ion beams used in IAD coatings can control the microstructure of the coating, resulting in improved spectral performance and reduced reflection.

Vacuum coating is a versatile technology that can be utilized to create a variety of filter types for different applications. For instance, longpass filters, shortpass filters, dichoric filters, and anti-reflection coatings may require less strict requirements, and therefore, we continue to utilize vacuum coating for these applications.

Coligh Optics has a wealth of experience in utilizing these three thin film coating techniques to produce optical glass filter coatings with exceptional quality and performance. They work closely with their clients to determine the best coating solution for their specific needs, ensuring that they receive a product that meets their requirements and exceeds their expectations.