Production Capability

At Coligh Optics, we are committed to achieving unparalleled optical quality and precision optical filters in all our manufacturing processes.

- We maintain strict adherence to ISO 9001:2015 standards, incorporating comprehensive testing and quality control procedures with fully traceable and documented protocols.

- Each stage of our production process involves rigorous operator inspection to ensure that all optical components and glasses meet our exacting standards.

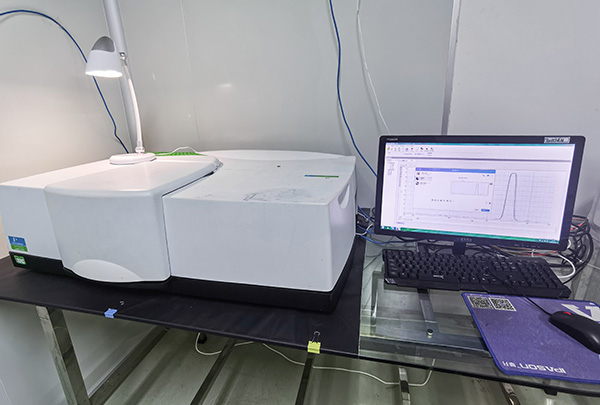

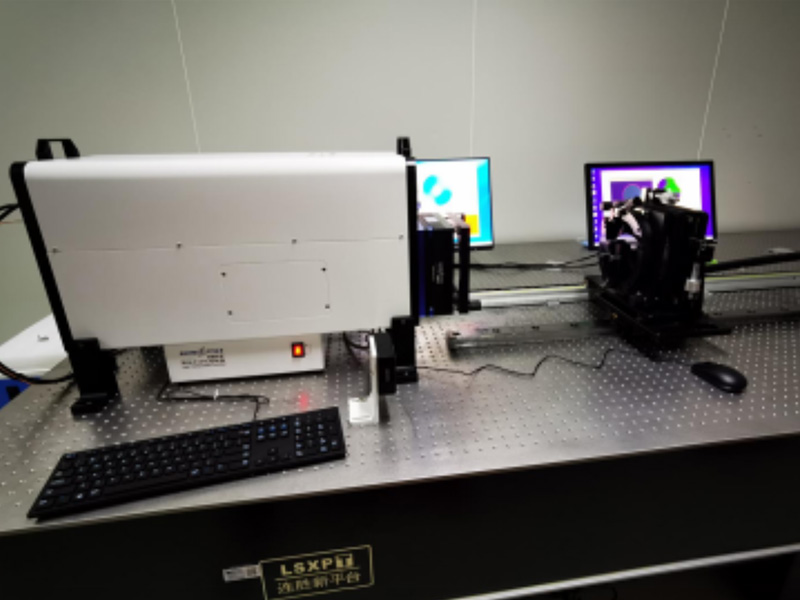

- We employ in-house interferometers, spectrophotometers, and other advanced testing and measuring equipment to ensure 100% precision in dimensions and other critical parameters.

- To guarantee the highest quality standards, we conduct a thorough visual inspection of each optical component before dispatch to eliminate any material issues or surface defects.

- Our unwavering dedication to quality assurance ensures that our customers receive the best optical components available in the market.

Quality control on the detail:

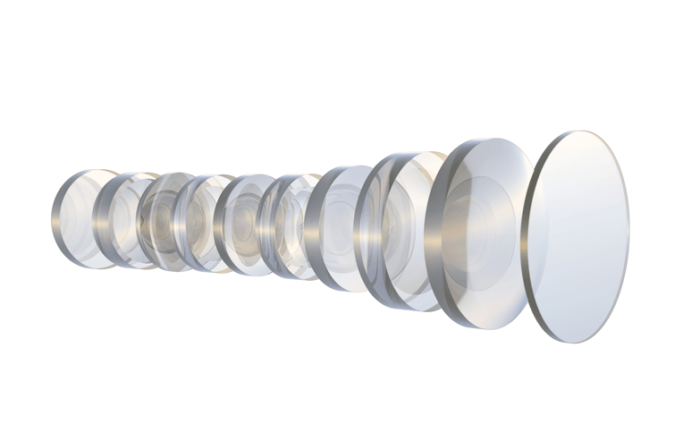

Raw Material: All materials needed for the manufacturing process, such as unpolished and uncoated glass substrates, filter frame materials, etc., are strictly inspected according to the drawings and the company’s inspection standards. Materials or batches that do not meet tolerance, surface finish, surface shape, parallelism, or other quality requirements are all returned to the supplier.

Grinding and Polishing: To achieve the required coating thickness, all glass substrates are polished and polished by experienced workers using advanced equipment.

Precision Coating: Experienced coating engineer operate advanced coating equipment to ensure consistent quality of filter and performance

Cleaning: Automatic ultrasonic cleaning machines and pure water machines are used to clean glass substrates.

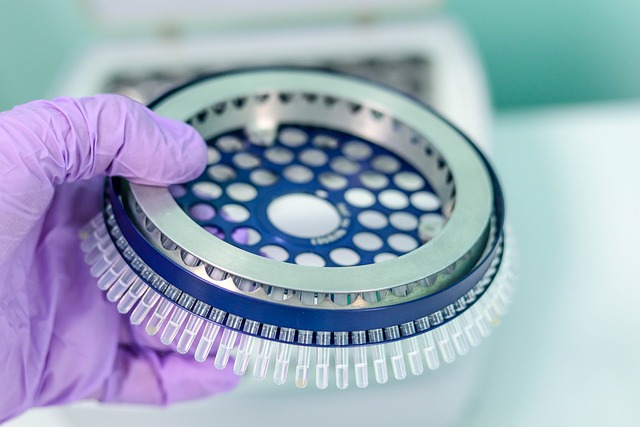

Thorough testing and inspection: After coating, the inspection department conducts tests on the adhesion, transmittance, reflectance, optical density, interference pattern, surface shape, parallelism, surface finish, angles, or other customer requirements of the coating.Before leaving the facility, all products undergo extensive testing to ensure they meet customer specifications and industry standards.

Experienced team: Coligh’s team of coating, inspection and application experts has years of experience in the industry, and they use their knowledge and expertise to deliver superior products and services.

State-of-the-art facility: Chroma’s manufacturing facility is equipped with the latest technology, ensuring that products are produced efficiently and to the highest quality standards.

Customer satisfaction: Chroma is committed to providing excellent customer service and ensuring that every customer is satisfied with their products and services.