Aspheric lenses possess varying radii of curvature across their surfaces, enabling them to eliminate spherical aberration and other optical errors that are uncorrectable by conventional spherical lenses. The application of aspheric lenses results in improved light collection accuracy and enhanced imaging quality for the entire optical system. Aspheric lenses are also advantageous in reducing weight, volume, and cost, as they can replace multi-lens systems. These lenses find significant usage in various fields such as night imaging, instrument flaw detection, infrared thermal imaging, infrared temperature measurement, infrared distance measurement, and other related applications.

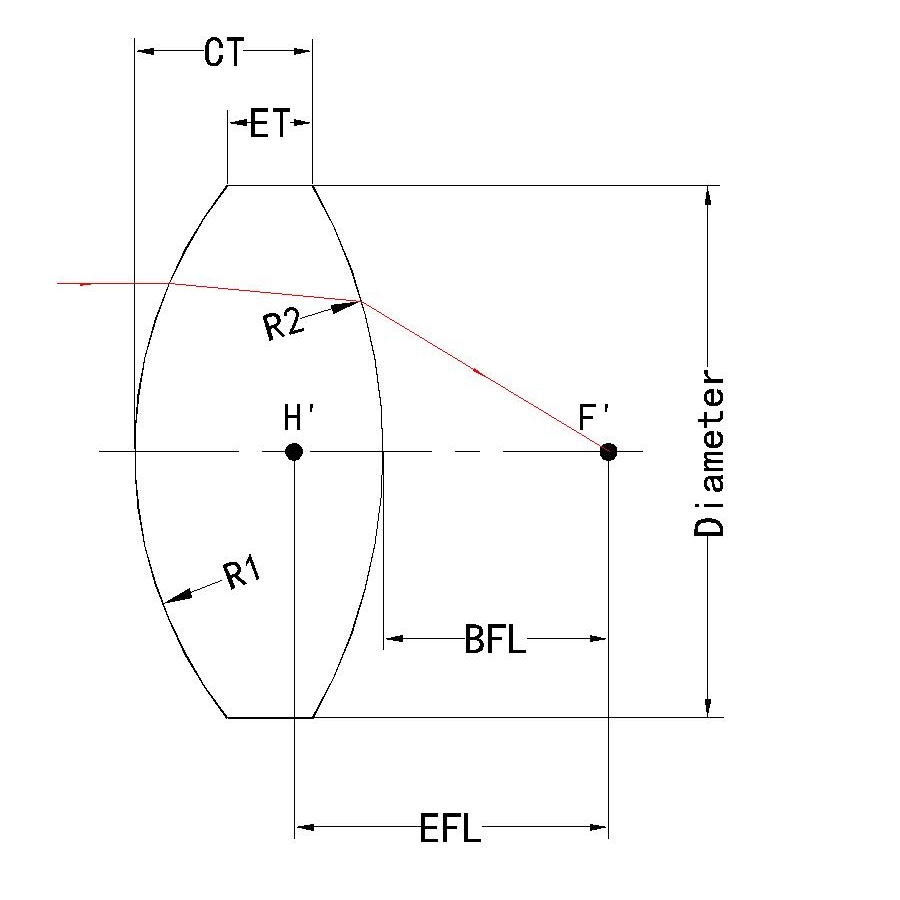

Examples of the aspherical lens we have processed:

| Model |

Diameter |

Focal length |

Back intercept |

Center thick |

Edge Thickness |

Material |

Shape |

R1 |

R2 |

| A455 |

10 |

5.5 |

|

4 |

|

H-ZF13 |

As per drawing above |

Aspherical |

Aspherical |

| A387 |

14 |

5.4 |

1.4 |

6.6 |

1.9 |

H-K9L |

As per drawing above |

Aspherical |

Aspherical |

| A377 |

10 |

6.8 |

5.2 |

3.6 |

6 |

H-K9L |

As per drawing above |

Aspherical |

8.2 |

| A143 |

40 |

29.5 |

20.9 |

15.5 |

3.75 |

H-K9L |

As per drawing above |

Aspherical |

67.75 |

Coligh boasts of internationally advanced milling, polishing, and other precision processing equipment, alongside sophisticated testing facilities. Its wide range of products includes optical spherical lenses, cylindrical lenses, and coating products. Furthermore, Coligh provides comprehensive application solutions, spanning from design, sample testing, to mass production, in a bid to ensure that customers’ specific application requirements and usage needs are met. Coligh’s products are widely used in various fields such as aerospace, industrial equipment, scientific research, medical treatment, testing instruments, and other related domains. Through years of continuous efforts, Coligh has been delivering high-quality products that can effectively cater to the diverse needs of its customers.

Our aspherical lens custom capability:

|

Material

|

Processing Parameter

|

Precision grade

|

| Normal |

Medium |

Custom |

|

Monocrystalline silicon

Single crystal germanium

Chalcogenide glass

Zinc selenide

Zinc sulfide

Optical glass

Quartz

Calcium fluoride

|

Thickness allowance |

±0.5mm

|

±0.1mm |

-0.02mm

|

| Size allowance |

±0.5mm |

±0.1mm |

±0.02mm |

| Eccentricity |

3′ |

1′ |

50″ |

| Curvature error |

1% |

0.6‰ |

0.2‰ |

| Surface ( PV ) |

1μm |

0.5μm |

0.2μm |

| Surface Quality |

60/40 |

40/20 |

10/5 |

| Effective Aperture |

>90% |

>90% |

>90% |

| Surface Roughness |

/ |

/ |

RMS<0.04μm |

| Focal length: ±5mm~±1000mm±2% |

| Diameter: 10mm to 75mm+0.0/-0.2mm |